To spread the word about the importance of lifting safely, we will be blogging a series of essential guides on how you can make sure equipment is used correctly at your site.

Here’s your first installment – our guide to using webbing straps and round slings.

Take a look at our top tips on how to choose the right sling for your job, lift safely and look after your accessory.

Choosing your sling

Size, shape, weight of load and lifting environment will affect your choice of lifting sling so take great care in checking what lifting capacity and length you will require to safely complete the job.

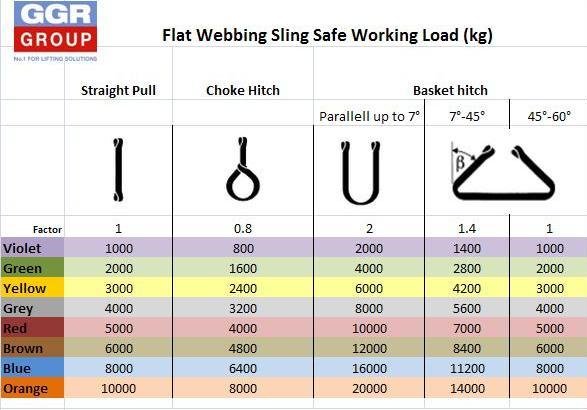

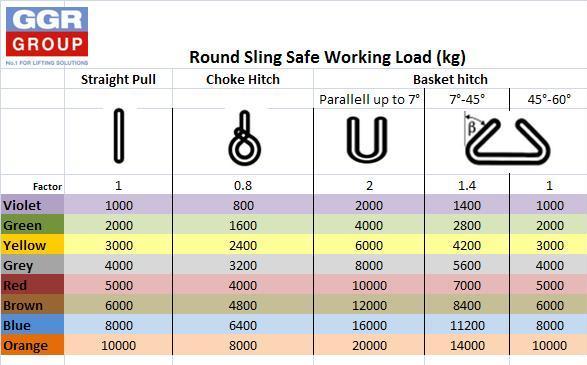

GGR Group has a range of webbing slings which are available to hire or purchase. We stock a range of lengths and lifting capacities, which are colour coded for easy identification.

To find out more click on the following links:-

Polyester continuous round slings

Flat Simplex polyester webbing sling

Flat Duplex (two-ply) polyester webbing sling

We also have our own bespoke sling service available for customers wanting to lift larger loads. Flat slings with a maximum 20 tonnes capacity up to 30 meter long or continuous round slings with a maximum 100 tonnes capacity up to 18 meters long can be made to order. For more information contact us at info@ggrgroup.com

Before use

Check for any damage before using your sling as this can seriously affect its safe lifting capacity. Inspect the full length of the sling for any significant abrasion, surface chafing, cuts, cracked end fittings, loose, cut or incomplete stitching on seams or eyes. Look out for signs of chemical damage such as softened areas or powdering. Perhaps use a new sling as a comparison to assess any damage, but do not use a sling you are unsure about or attempt to repair it yourself.

The equipment you are using with the webbing strap also needs to be safety checked. Are there any sharp edges on the apparatus or load you are lifting that could damage the textile sling? Sleeves or patches can be used on any areas that may need some extra protection. The lifting equipment also needs to be compatible with a sling, for example eyes could be stretched wider if the body of the hook is too big, causing excessive load is put onto the more vulnerable sewn parts.

If you would like any advice on whether a sling is safe to use, email us at help@ggrgroup.com or ring our North headquarters on 0161 683 2580.

During use

Trained operators familiar with using slings should plan the lifting and lowering of the load beforehand to ensure that the job can be carried out safely.

The weight of the load should be as uniformly spread across the sling as possible, and if using multiple slings for a single load the weight should be distributed evenly between them. This should ensure that the load is stable enough not to tilt or fall when being lifted.

Dragging slung loads across the ground or rough surfaces, pulling a sling out from beneath a load when it is resting on it and shock loading can all cause serious damage to the sling.

To keep your sling in perfect working condition make sure it is kept away from UV radiation, sunlight and sources of heat. If using a sling around chemicals or other extreme conditions, such as high temperatures, seek advice beforehand.

The charts below show the lifting capacity of webbing slings, use them to work out how you can to safely lift your load.

Trackback URL: https://www.ggrgroup.com/news/webbing-sling-webbing-strap-guide/trackback/