A tricky glass replacement job was made quick, simple and safe when a line-up of three lifting machines were hired from GGR to help take this glass replacement job from start to finish in a day.

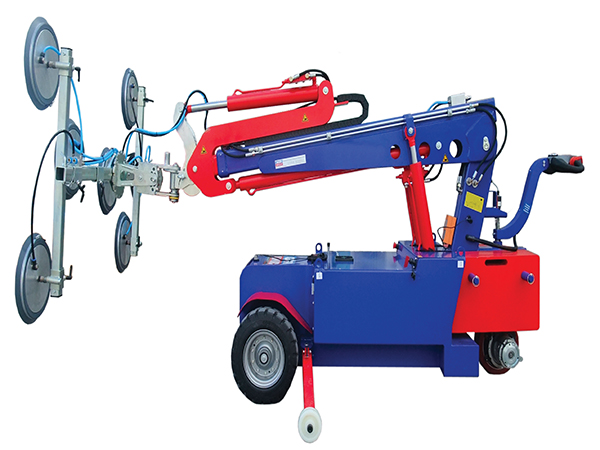

Once unloaded at the roadside, a G20 pick and carry crane and Oscar 1000 glazing robot were driven through the apartment building to reach the lifting location where a glass end unit needed to be replaced.

The vacuum pads of the 1000kg Oscar robot were attached to the outside surface of the damaged 275kg glass and held it in place while the brackets were removed so it could then be lifted out. The G20 crane on the opposite side of the glass was fitted with a 500kg capacity MRTA611 Six-in-Line vacuum lifter to lift out and remove the unit.

The same process was then put into reverse for the installation, the 2 tonne capacity G20 compact crane and vacuum lifter were used to lift the new 3.5 metre tall panel into position with the Oscar robot then holding it in position while the brackets were fixed.

The same process was then put into reverse for the installation, the 2 tonne capacity G20 compact crane and vacuum lifter were used to lift the new 3.5 metre tall panel into position with the Oscar robot then holding it in position while the brackets were fixed.

With some help from GGR Group this stunning apartment building was soon back to looking its best. Our compact lifting equipment is often hired for reglazing work, for example the Glass Sherpa at a London bookies and our glass vacuum lifters at Manchester’s Beetham Tower skyscraper.

Trackback URL: https://www.ggrgroup.com/news/oscar-1000-glazing-robot-makes-glass-switch-simple/trackback/