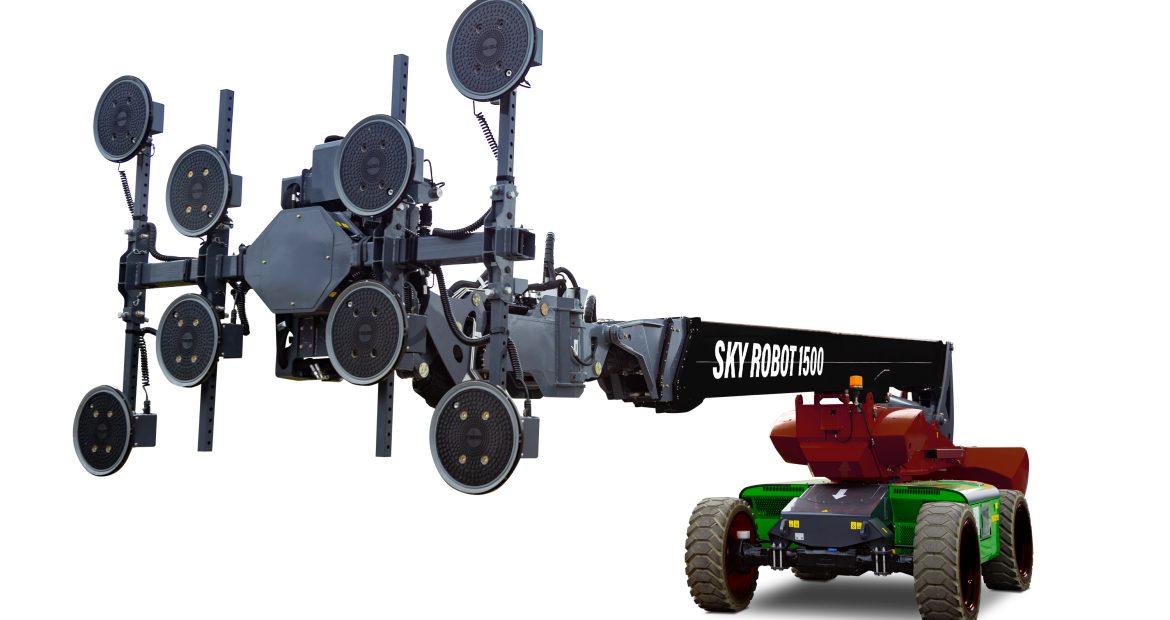

The Sky Robot 1500 is a glazing robot designed to change the market. Glazing robots are typically compact machines that can be driven by an operator between locations and are able to lift heavy glass. They provide an alternative solution to needing to hire out multiple products for a small project. Without a glazing robot, products such as a crane, glass vacuum lifter, and an overhang beam would be needed.

By using a glazing robot you can perform heavier lifts and complete the glass lift with just one machine. This means less time and manpower per job. This is because using multiple machines means more operators are needed.

7 Pros of the Sky Robot 1500

This glazing robot is a UK first with the 26.16m height it is able to achieve when installing glass. As before glazing robots could only lift glass to one or two storeys this is amazing in itself. This massive height of 26.16m can be achieved while lifting 1200kg. Or alternatively, if the height is reduced to 21.93m you can lift the full 1500kg maximum SWL.

Take a look at the Sky Robot in action here.

Fully Articulating 3D Head

The Sky Robot has the benefit of this unique feature. With the 3D head, the operator can rotate the rated loads a complete 360˚ for easily turning glass for normal or inside-out installation. The head can also tilt 90˚ up and 30˚ down making the machine ideal for installing canopy glazing and glass from above. You can slew 80˚ left and right, allowing for installing glazing from the side when access is restricted.

Four-Wheel Drive

Installing glass can often require millimetre-precise positioning. This can be a struggle to achieve if the operator does not have plenty of experience or the equipment is not suited to the job. With the Sky Robot 1500’s four-wheel drive it is simple to make small adjustments to the position of the glass. This larger machine benefits highly from the four-wheel drive as it reduces the difficulty of driving around busy construction sites.

Continuous Rotating Base

When operating any type of machinery finding the perfect position for installing an object to then have to move from that position is highly frustrating. With the 360˚ turntable, the operator can easily turn the base to grab the next glazing unit before returning to its original position. This also means there is less need for moving the entire glazing robot every time the installation position changes.

Fully Radio Remote Controlled

When wanting to achieve highly accurate glazing placement a radio remote control is the best way to do it. By using the remote on this large machine, the operator is able to move freely to observe the positioning of the glazing. Some operators have even made use of access equipment to get as close as possible to the installation for maximum accuracy.

8 Independent Suction Cups

The higher a load is lifted the more unsafe it can potentially become. This is why the 8 independent cups are such an important part of the Sky Robot 1500. The independent vacuum cups mean that in the unlikely chance one fails, the other cups can support the load until you can return the load to the safety of the ground.

100% Battery Powered

As an ideal machine for installing canopy glazing with low-marking tyres, it makes sense for it to be battery-powered too. With zero emissions and no pollution, you can take the Sky Robot anywhere without issue in low-emission zones. The Sky Robot also offers the opportunity for more indoor glass installations, especially for canopy glazing where installing the glass from above may not be an option.

The Sky Robot is available now for hire with the option of hiring a skilled operator with it. To hire the Sky Robot 1500 or speak to one of our experts contact us by phone or clicking here. GGR Group have a selection of products available to suit all your lifting needs. You can browse our other glazing robots here.

Trackback URL: https://www.ggrgroup.com/news/sky-robot-1500-pros/trackback/